CHOOSE HHES

Jinzhou Hanwha Electric Equipment Co., Ltd. was established in May 2003 and was jointly invested and set up by Wind Automotive Group and Dongyou Co., Ltd. of South Korea.

HHES PRODUCT CENTER

The company has an independent research and development institution to carry out design and development according to customer requirements. At the same time, the company cooperates with foreign equipment manufacturing companies to design automatic and semi-automatic armature production equipment, and established advanced production line. The company adopts lean production management to guarantee the consistency and stability of products. The current annual capacity is 8 million units, and the main customers areJinzhou Halla Electrical Equipment co., ltd., Shenyang Xuantan Automobile Parts Co. LTD, United Automotive Electronic Systems Co. Ltd, Mahler Electric Drive, Russia PRAMO Company, BOSCH, DELPHI, etc.

HHES NEWS

19

12

2025

With years of deep engagement in the industry, Jinzhou Hanwha Electric Components Co., Ltd. has consistently integrated the concept of green development into every aspect of its production and operations. Driven by a dual approach—“green foundations and intelligent empowerment”—the company has forged a development path that equally emphasizes ecological and economic benefits. Recently, it was successfully awarded the provincial-level “Green Factory” title.

27

12

2023

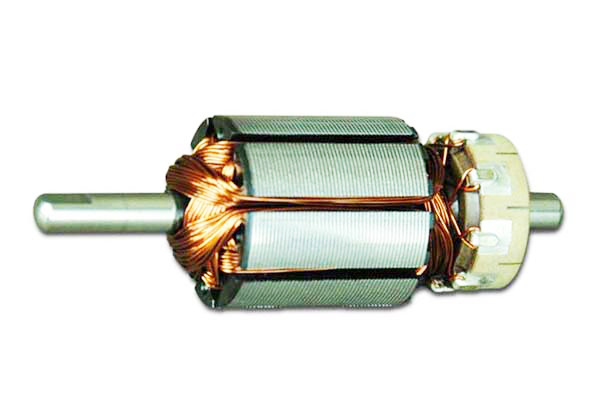

Provides manufacturing services for a variety of automotive motor armatures

The automotive armature is one of the core components of an automotive motor, playing a crucial role in the entire automotive electric system. As a company providing manufacturing services for a variety of automotive motor armature products, we are committed to providing high-quality armature solutions for automotive and motor manufacturers. In automotive motors, the armature is the key part that converts electrical energy into mechanical energy. It consists of many windings that generate force and motion through interaction with a magnetic field. Therefore, the design and manufacturing quality of the armature directly affect the performance and efficiency of the motor. Our company has advanced manufacturing equipment and a technical team that can customize various types and specifications of automotive armature products according to customer requirements and needs. Whether it is a DC motor or an AC motor, we can provide high-performance armature solutions. Our products are widely used in various vehicle types such as automobiles, motorcycles, and electric bicycles. In the manufacturing process of automotive armatures, we strictly control each link to ensure product quality and reliability. We use high-quality materials and advanced production processes to ensure that the armature has good thermal stability, wear resistance, and corrosion resistance. At the same time, we also conduct strict quality inspections and tests to ensure that each armature meets industry standards and customer requirements.